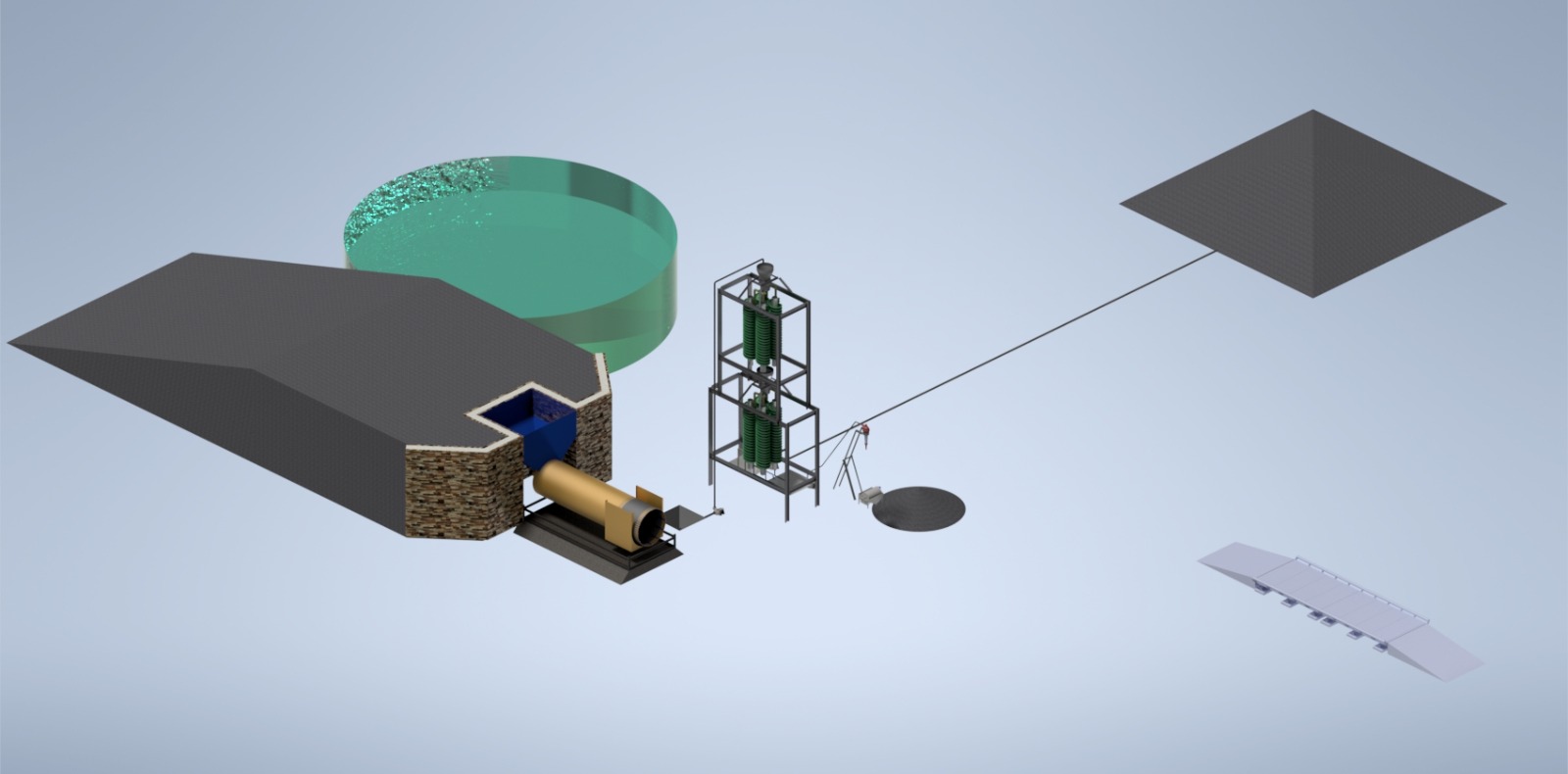

alluviel chrome washplants

Neptune Sator has perfected alluvial chrome washing through the innovative use of spiral technology, achieving over 46% chrome recovery. Our advanced spiral classifiers and concentrators efficiently separate chrome from associated minerals, ensuring high-grade yields. We also focus on minimizing iron content, resulting in a purer, more valuable product. Trust Neptune Sator to deliver superior alluvial chrome processing solutions with optimal recovery and quality.

Neptune Sator has mastered alluvial chrome beneficiation through the application of advanced spiral gravity separation technology, achieving chrome recoveries exceeding 46%. Our process utilizes high-throughput spiral classifiers and multi-stage sluicing to enhance mineral stratification and maximize physical separation efficiency. By optimizing process parameters such as feed pulp density, rotational speed, and wash water distribution, we effectively concentrate chrome while minimizing iron gangue content, resulting in a high-purity product. Leveraging principles of hydro metallurgy and fluid dynamics, our approach ensures enhanced liberation and recovery of chrome, delivering superior product quality and operational efficiency.

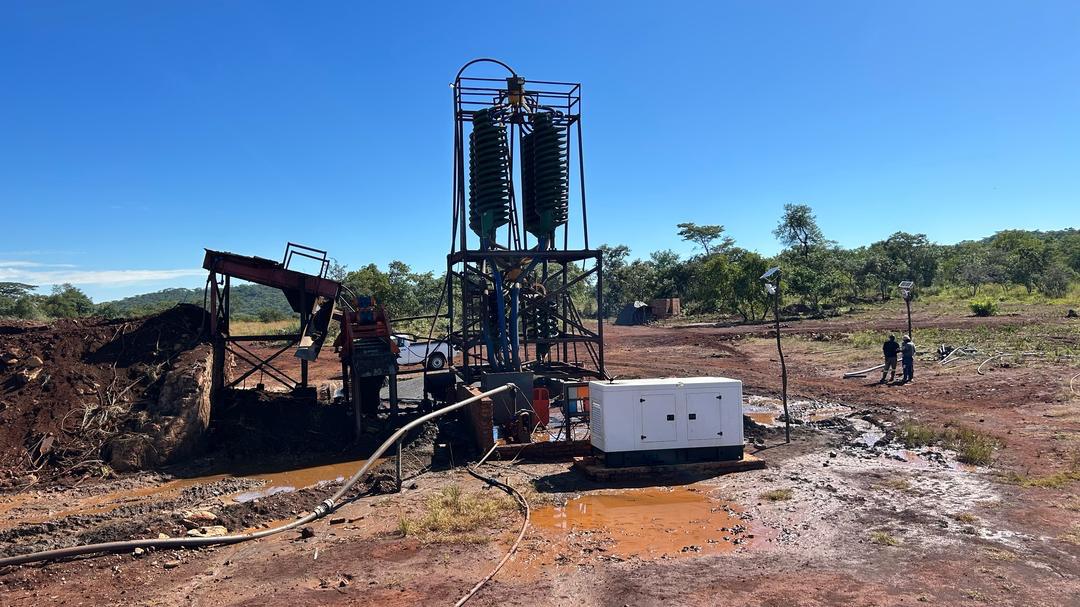

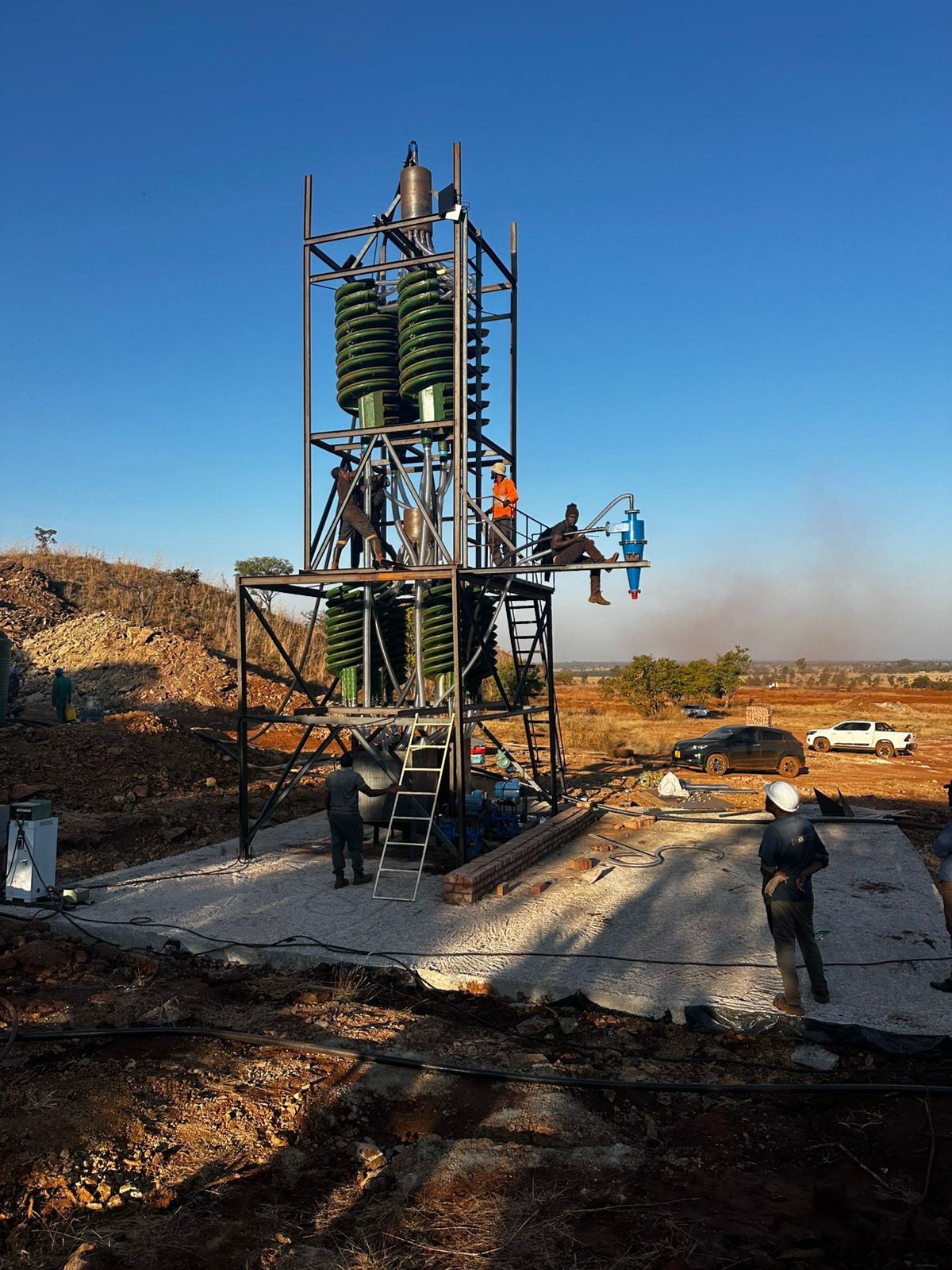

Project Gallery