Our Portfolio

Explore our successful projects in mining consultancy Zimbabwe, engineering consulting services, and specialized accounting solutions.

alluviel chrome washplants

Neptune Sator has perfected alluvial chrome washing through the innovative use of spiral technology, achieving over 46% chrome recovery. Our advanced spiral classifiers and concentrators efficiently separate chrome from associated minerals, ensuring high-grade yields. We also focus on minimizing iron content, resulting in a purer, more valuable product. Trust Neptune Sator to deliver superior alluvial chrome processing solutions with optimal recovery and quality.

Client: various nothern and southern dyke establishments

Heap leach

"Neptune Sator expertly designs and constructs advanced heap leach pads, optimizing metallurgical processes for efficient gold leaching. Our innovative solutions enhance recovery rates while ensuring environmental sustainability. Rely on us to elevate your mining operations with precision in metallurgical engineering and construction excellence."

Client: Raventa Private limited

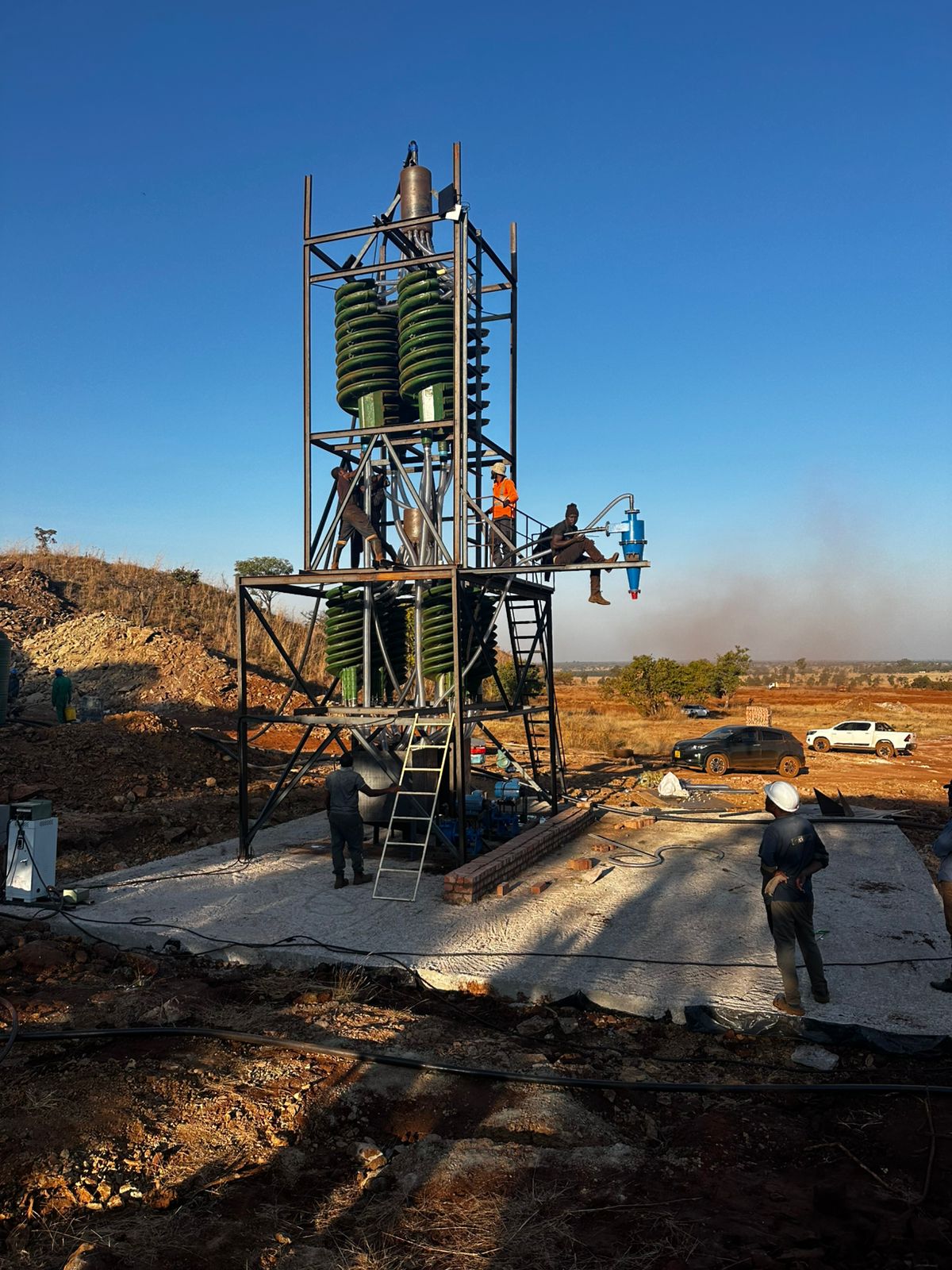

20 tph Antimony WashPlant

Neptune Sator designed a crushing and spiral washing plant for antimony ore, achieving efficient separation of 70% massive stibnite and 30% disseminated mineral.

Client: Alke resources and Umfazo Holdings

Completed: December 2025

Astra Metalite Alluviel Chrome Washplant

Neptune Sator was engaged to design, construct, and commission a 60 TPH ..

Client: astra metalite

Completed: November 2025

Gravity Gold Recovery Curcuit

Neptune Sator in collaboration with a well seasoned Metallurgical engineer MR Douglas Chitida designed a comprehensive gravity gold processing circuit for BlueFlag in Zambia, focusing on efficient mineral separation and high recovery rates. The plant incorporates modular gravity concentrators, including sluice boxes and Knelson concentrators, optimized for the processing of alluvial and free-milling gold ores. The design emphasizes operational simplicity, scalability, and environmental sustainability, ensuring reliable performance and maximizing gold recovery in a cost-effective manner.

Client: Blue Flag Investments Zambia

Completed: June 2024

Impressed by Our Work?

Let us help you achieve similar results for your mining, engineering, or accounting project.