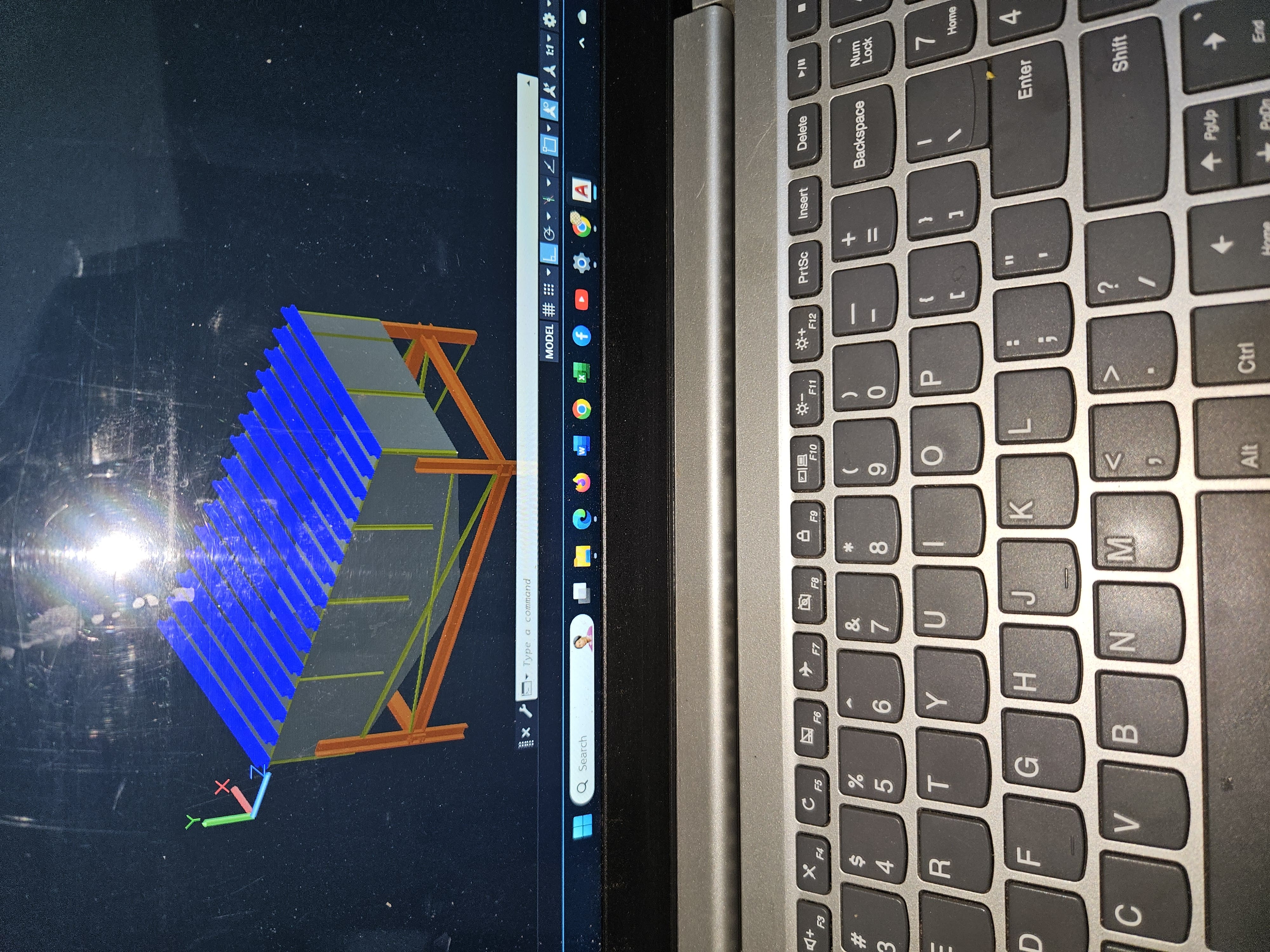

Gravity Gold Recovery Curcuit

Neptune Sator in collaboration with a well seasoned Metallurgical engineer MR Douglas Chitida designed a comprehensive gravity gold processing circuit for BlueFlag in Zambia, focusing on efficient mineral separation and high recovery rates. The plant incorporates modular gravity concentrators, including sluice boxes and Knelson concentrators, optimized for the processing of alluvial and free-milling gold ores. The design emphasizes operational simplicity, scalability, and environmental sustainability, ensuring reliable performance and maximizing gold recovery in a cost-effective manner.

Project Overview

Neptune Sator was contracted to design, install, and commission a 10 TPH gravity gold processing circuit for BlueFlag in Zambia. The system comprised a comprehensive flow sheet including a crushing circuit to prepare the ore for milling, a ball mill to achieve the desired liberation of gold particles, and a gravity concentrator setup to maximize gold recovery. The design incorporated parallel processing lines, with one line dedicated to the primary gravity concentrator system, while a second parallel line featured a washplant specifically tailored for the recovery of nuggets and coarse gold particles. The installation was executed to ensure operational efficiency, ease of maintenance, and scalability for future capacity upgrades. Upon commissioning, the plant demonstrated reliable performance, achieving targeted recovery rates and delivering a cost-effective solution for artisanal and small-scale gold mining operations.

Key Objectives

- Increase gold recovery rates

- Reduce operating costs

- Improve throughput capacity

- Enhance safety standards

Results Achieved

- 25% increase in recovery rates

- 15% reduction in operating costs

- 30% improvement in throughput

- Zero safety incidents during implementation

Project Gallery

More Projects

Explore more of our work in Mining Consultancy